Concept Zero − The invisible revolution

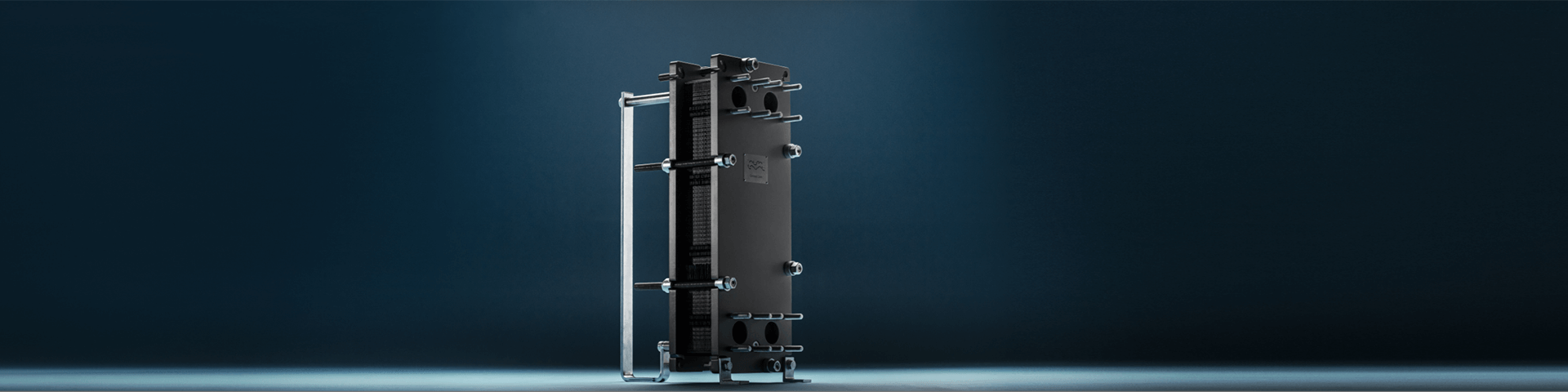

A heat exchanger is a heat exchanger, right? Could you tell the difference? At Alfa Laval, we are committed to do our part in enabling a decarbonized future. With a commitment of becoming carbon neutral by 2030 we aim to eliminate emissions from our products, from raw material extraction to end-of-life. Concept Zero is a crucial step on this journey, pushing the boundaries to develop a truly carbon-neutral plate heat exchanger with no misleading schemes.

Together with SSAB we are making this a reality. Compared to our current ones; it looks the same, you cannot spot the difference. Once ready and delivered these heat exchangers will be installed in industrial processes that matters to most but are basically not visible.

But – this will change the way we run industrial operations. Reducing carbon emissions from both the material we use and the products and processes we run. Making them more sustainable. They can be an important step in the ongoing transition towards a more sustainable society.

Just imagine the impact of heat exchangers like this one, being installed in various industrial processes all over the world. That is why we call this “an invisible revolution”.

This is Concept Zero

This is Concept Zero

Concept Zero is our vision and target to produce the world’s first carbon neutral heat exchanger by 2030. It will be a heat exchanger using fossil-free steel and recycled material in the gaskets. Additionally, the heat exchanger is prepared to easily be recycled. A huge step already now on our journey towards a fully carbon neutral heat exchanger.

Alfa Laval and SSAB joined forces producing the first fossil-free heat exchanger

Partnerships are crucial to go that extra mile to find new innovative solutions for accelerating sustainable solutions. Alfa Laval has signed an agreement with SSAB, the global Swedish steel company, to develop and commercialize the world’s first heat exchanger made from fossil-free steel. The goal is to have the first unit made from hydrogen-reduced steel ready for use in 2023.

Want to learn more about Concept zero?

Contact us today for more information about Alfa Laval's carbon-neutral plate heat exchangers.

Konsulent? Systemintegrator?

Er du konsulent? Se her! Med kompetanse og erfaring fra tiår innen varmeveksling, tilbyr Alfa Laval kunnskapsrike ressurser som kjenner dagens oppvarmings- og kjølingsbehov. Få svar på komplekse spørsmål om alt fra energieffektivitet til naturlige kjølemidler, sammen med nyttige verktøy som gjør det enklere å finne riktig teknologi for ditt behov.

Re-Made to matter

Alfa Laval and Stena Recycling have teamed up create the smart, sustainable and easy-to-use Re-Made to matter exchange programme. This gives us the possibility to recover as much as 100% of the valuable metals found in old heat exchangers. By replacing them with more modern designs, we can also enable efficiency improvements for energy savings as well as a reduced carbon footprint.