Technical information - Welded spiral heat exchangers

No supplier on the market has more experience than Alfa Laval when it comes to designing and manufacturing spiral heat exchangers. Over fifty years of expertise has gone into making them the ultimate solution to tough process problems. Keep reading to learn about the technology, available models and unique innovations that make it possible.

How do spiral heat exchangers work

Spiral heat exchanger working principle

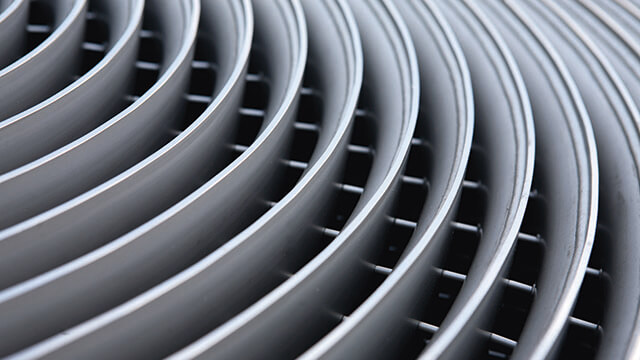

Alfa Laval spiral heat exchangers are circular units containing two concentric spiral flow channels, one for each fluid. The different media flow counter currently: one fluid enters the centre of the unit and flows towards the periphery, the other enters the unit at the periphery and moves towards the centre. The channels are curved and have a uniform cross section. There is no risk of intermixing.

The product channel is normally open on one side and closed on the other. The channel for the heating/cooling medium can sometimes be closed on both sides, depending on the cleanliness of the heating/cooling medium. Each channel has one connection in the centre and one on the periphery of the heat exchanger.

Design of spiral heat exchangers

The single-channel geometry also creates a scrubbing effect that we refer to as the SelfClean™ design. If fouling does occur in the heat transfer channel, the cross-section of this part of the channel is decreased. However, since the entire flow must still pass through the channel, the velocity increases, the resulting fluid force then flushing away any accumulations of deposits as they form.

Compare this design with shell-and-tube heat exchangers where the flow enters different tubes in parallel. When tubes start to foul, pressure drop increases pushing the fluid to find alternative flow paths. The result is that fouling and clogging of the tubes happens very quickly. With Alfa Laval spirals, on the other hand, fouling and clogging is virtually eliminated.

Our welded spiral product range

SpiralPro for væske-til-væske-oppgaver

Alfa Lavals SelfClean™-konstruksjon gjør SpiralPro-varmevekslerne til et smart valg ved arbeid med skitne væsker, slam, emulsjoner, oppslemminger, fibre eller væsker med partikler. Siden væskene strømmer kontinuerlig i en enkelt kanal, virker væskekraften mot eventuelle avleiringer ved å "skyve" dem gjennom kanalen og ut i den andre enden.

Det kompakte designet til SpiralPro-modellen tillater ofte at man kan erstatte flere store skall-og-rørvarmevekslere med en enkelt SpiralPro-varmeveksler. Dette skaper betydelige infrastrukturfordeler i tillegg til å redusere vedlikeholds- og rengjøringskravene. Hvis enheten trenger rengjøring, kan dekslene enkelt fjernes for vask med en hydrostråle.

Bruksområder

- Avleirende væsker som inneholder faste stoffer, fibre, flytende stoffer og slam

- Væske-til-væske forvarming, oppvarming, kjøling, veksling og varmegjenvinning

SpiralPro for dampvarmeoppgaver

SpiralPro-varmevekslere som er optimalisert for oppgaver som innebærer dampoppvarming av væsker med høy avleiring, er også tilgjengelige. Som alle SpiralPro-enheter er disse fullt tilgjengelige for rask og enkel rengjøring med hydrostråler.

De motgående strømmene sikrer også at man kan ha temperaturer som ligger svært nær hverandre og dermed gir maksimal termisk effektivitet.

Bruksområder

- Avleirende væsker som inneholder faste stoffer eller fibre, flytende stoffer, slam og andre utfordrende væsker som krever oppvarming med damp

SpiralCond for oppgaver med vakuumkondensering og fordamping

SpiralCond-varmevekslere har en svært effektiv løsning for utfordrende tofasede oppgaver, inkludert både kondensering og fordamping (reboiling). Det kompakte designet til SpiralCond og det faktum at den er satt opp vertikalt, gir i et meget lite miljøavtrykk, sammenlignet med sammenlignbare skall- og rørvarmevekslere, samtidig som de reduserer støttestrukturer og rørkompleksitet.

SpiralCond-enheter har tverrflyt i stedet for motstrøm. Hver enhet er tilpasset i henhold til den tiltenkte oppgaven, med en kanalavstand som er justert for å gi det laveste trykkfallet. SpiralCond er derfor ideelt egnet for oppgaver som krever vakuumkondensering.

Bruksområder

- Gasser: ren damp og blandinger med inertgasser

- Damp/væske: toppkondensatorer, reflukskondensatorer, vakuumkondensatorer, ventilkondensatorer, reboilere med avleirende væsker, gasskjølere

SpiralCond i stablet kolonnekonfigurasjon

For kondenserings- og fordampningsoppgaver der flere kjølemedier er involvert, kan Alfa Laval levere SpiralCond-varmevekslere integrert i en kolonne. Som den enkle frittstående SpiralCond har denne konfigurasjonen kryssflyt og åpne kanaler for ekstremt lavt trykkfall i vakuumsituasjoner.

Den høye effektiviteten til SpiralCond gjør at kolonnen kan være både lavere i høyde og mindre i diameter enn tradisjonelle kolonneløsninger, noe som gir store besparelser i infrastruktur- og installasjonskostnader.

Bruksområder

- Damp-væske: toppkondensatorer, reflukskondensatorer, vakuumkondensatorer og ventilkondensatorer

Unique features of Alfa Laval Welded spiral heat exchangers

SelfClean™

Superior cleaning and extended performance

The SelfClean design of Alfa Laval spirals provides a reliable solution for fouling and clogging in duties involving challenging fluids, sludges, emulsions, slurries, fibres or particle loaded liquids.

Each circuit on a spiral unit consists of a single flow channel. This continuously curving, single-channel geometry creates high turbulence to minimize fouling from the start. If fouling does start to occur, local velocity increases, since the entire flow must still pass through the channel. This creates a scrubbing effect that flushes away any accumulations of deposits as they form.

An additional benefit of this design is that it eliminates the risk of dead spots and stagnation for more efficient heat transfer.

RollWeld™

Automated, reliable channel enclosure

The manufacturing of Alfa Laval’s spiral heat exchangers incorporates an automated process for bending the edge of the channels. This is followed by a cold-metal-transfer automatic welding machine for the final closure weld.

The combined effect of this so-called RollWeld technique is consistent quality of the channel closure. That, in turn, is critical for the strength and corrosion resistance of the channel welds and thus the reliability of the overall unit.

HighP™

A custom solution for high-pressure duties

For customers whose processes demand higher design and differential pressures than traditional spiral heat exchangers can provide, Alfa Laval offers capabilities to fully tailor a unique solution to match their needs.

We design our HighP spiral heat exchangers using a range of features, including a double gasket system, a self-supporting internal coil, and a special body and shell with bolted cover. Our experienced engineers work with you throughout the design process to make sure you get the ideal heat exchanger for your specific challenges.

HEXpert selector tool

Quickly find the ideal welded plate heat exchanger for demanding process applications. Fill in information about your duty, and within five minutes you can explore a customized recommendation for an efficient thermal solution.