AS-H sequencing batch reactor

The Alfa Laval AS-H Sequencing Batch Reactor is an advanced technology for activated sludge biological wastewater treatment processes. It is ideal for processes that require flexibility of influent flow and organic load, and where effluent requirements are stringent. A patented floating decanter, menu of technology options, and the ability to work with challenging footprint limitations allow you to create a process that is tailored to deliver superior performance designed to your plant’s needs.

When flexibility and performance matter in your biological wastewater treatment process

- Simple robust design where all treatment steps occur in the same tank

- Fewer tanks and less equipment reduces cost

- Process guarantees available

- Highly automated process requires less manpower

- Easy to retrofit into existing plants and earthen lagoons, or available in a package plant configuration

Hvordan det virker

Complete package with flexible design

The Alfa Laval AS-H sequencing batch reactor brings together the key elements of advanced activated sludge technology including anaerobic, anoxic, cyclic aerobic, and sedimentation processes into a single reactor. A variety of materials and configurations are available, such as shop-fabricated rectangular designs or larger field erected circular designs. Alternatively, an existing tank may be retrofit to accommodate the process.

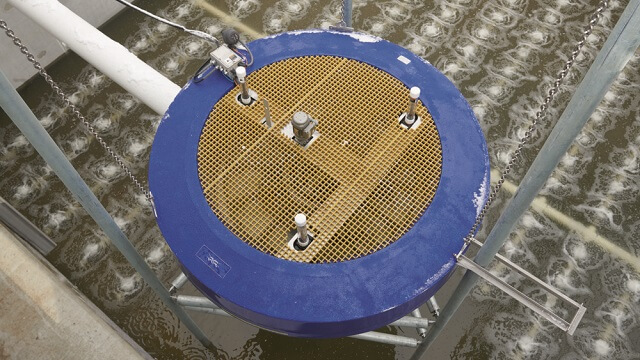

Patented Floating Decanter

At the core of the Alfa Laval AS-H SBR, is the floating decanter. There are several key features of this device that differentiate it from other solutions including:

- Adjustable V-notch weir to ensure precise decanting and minimize sludge disturbance

- Severe duty motors

- No underwater seals or valves

- Constant rate decanting

- Can be anchored anywhere within the aeration basin

The Alfa Laval AS-H floating decanter can also be purchased as a stand-alone product.

Flexible Process Control System

An expertly designed control system ensures optimum operation of your activated sludge SBR. Flexible options can range from:

- Flow proportional or Time-Based control

- True batch or Continuous Fill process

- User-friendly HMI, PLC, or a plant-wide SCADA system

Owners receive extensive training and ongoing support for their Alfa Laval AS-H SBR system.

Kundehistorier

Du er kanskje også interessert i …

Løsninger for sirkulær økonomi

Flere og flere renseanlegg oppdager fordelene med en sirkulær, helhetlig tilnærming til rensing av avløpsvann. Kostnadsbesparelser, redusert miljøpåvirkning og nye inntektsstrømmer fra gjenvunne ressurser er bare noen av disse. Hvert renseanlegg er unikt og har sine egne utfordringer og muligheter. Med vår ekspertise innen prosessering og vårt brede produktspekter kan vi hjelpe deg med å skifte til en sirkulær ressursflyt. Uansett om du er entreprenør, designer eller anleggsoperatør, kan vi hjelpe deg med å finne den optimale løsningen for ditt spesifikke prosjekt.

Reduce your environmental footprint and turn waste into value

All human, commercial and industrial activities produce waste products that are harmful to our environment unless treated. The world is therefore constantly on the look-out for ways to reduce pollution, provide clean water, use less energy and recycle energy already used. With growing populations and living standards plus water scarcity in many areas, there is also an increasing need for water reuse. See what you can gain from on-site water and waste treatment - and calculate your savings!